- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

|

Product Description

The bracket of the wind turbine tower barrel door is the key support structure of the tower barrel entrance, which uses a strong and durable material to ensure the stable opening and closing of the door. These brackets are well designed to withstand strong winds and other adverse weather conditions, while providing the necessary protection to prevent doors from accidentally closing or being damaged by wind. The stability of the support is essential to ensure the safe access of maintenance personnel to the tower barrel, and is usually equipped with a locking mechanism to ensure that the door is fixed when working inside the tower barrel. In addition, the design of the bracket also needs to take into account corrosion resistance and long-term maintenance convenience to meet the long-term operational needs of the wind farm.

|

Product Display

|  |

|  |

| Company Profile

Jiangsu VY Precision Machinery Co., Ltd.

Nestled in the esteemed Honglan Industrial Concentration Area of Lishui District, Nanjing—a city steeped in history and once the capital of six dynasties—Jiangsu VY Precision Machinery Co., Ltd. covers an expansive 35,000 square meters with a sophisticated construction area of 28,000 square meters. The company proudly boasts a registered capital of 20 million yuan.

Founded in 2009, Jiangsu VY Precision Machinery Co., Ltd. has flourished into a powerhouse in precision CNC machining for metal structures. Equipped with an extensive array of imported numerical control cutting, sheet metal processing, welding, and machining equipment, we offer unparalleled precision and scale. Our dedication to quality is underscored by our ISO 9001 International Quality Management System Certification, ISO 14001 International Environmental Management System Certification, and OHSAS 18001 International Occupational Health and Safety Management System Certification. Additionally, we hold prestigious qualifications such as ISO 3834 and EN1090 certification. Our core expertise lies in the design, manufacturing, and servicing of top-tier energy equipment.

|

Production Process

Cutting

Machining

Bending

Corrosion Protection

Welding

Packing

|

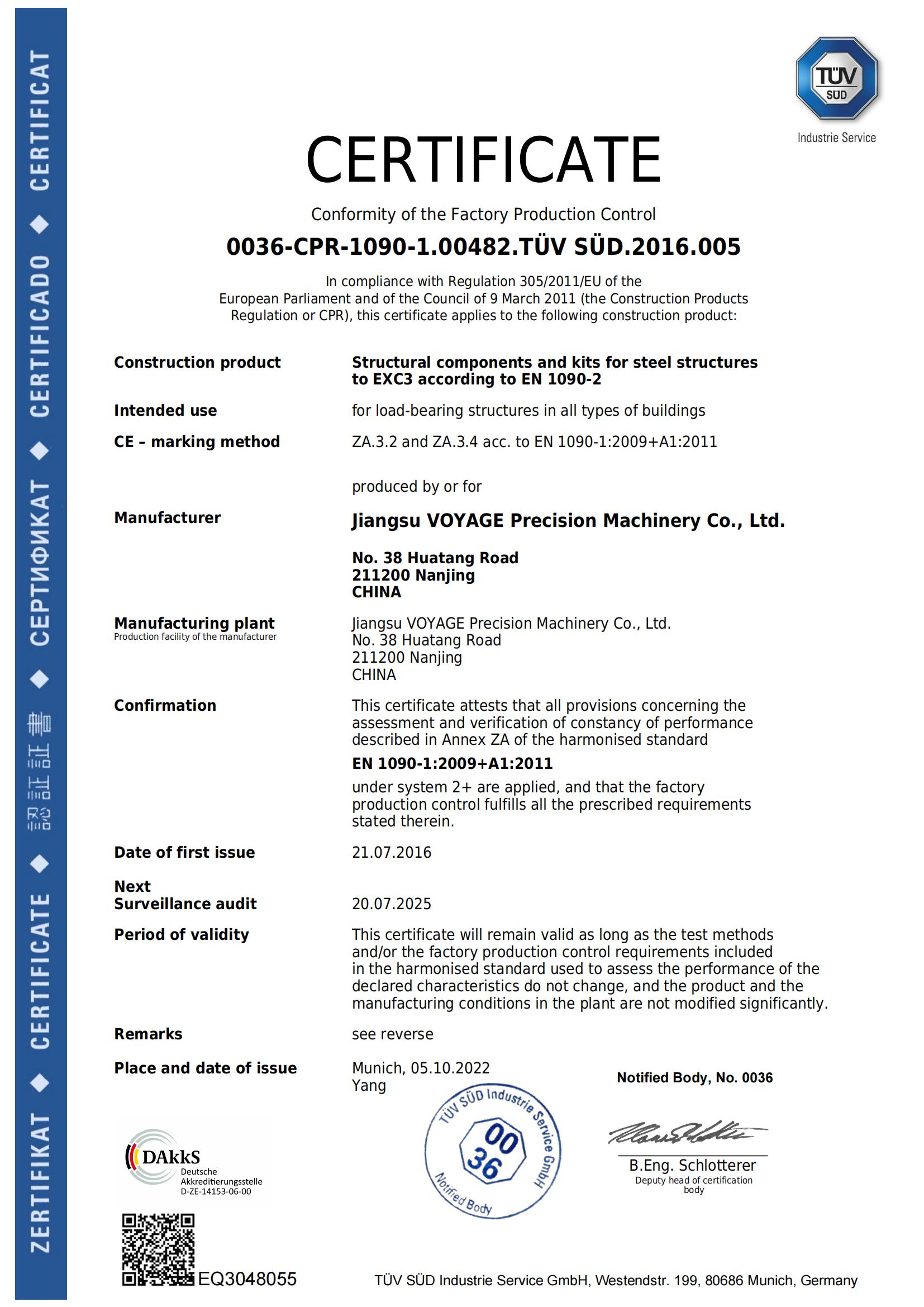

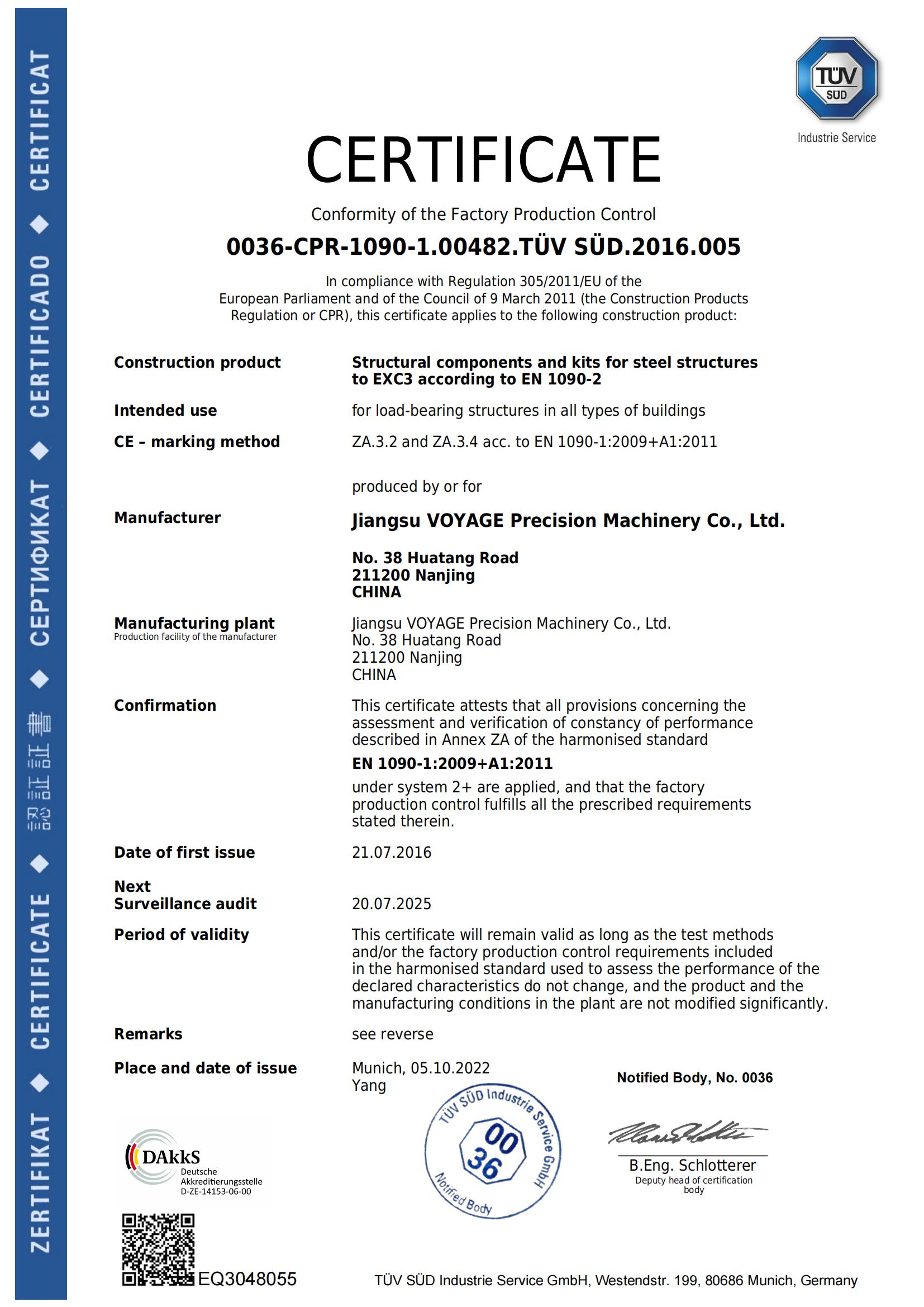

Certifications

ISO9001

ISO45001

ISO14001

EN1090

| Packaging & Shipping

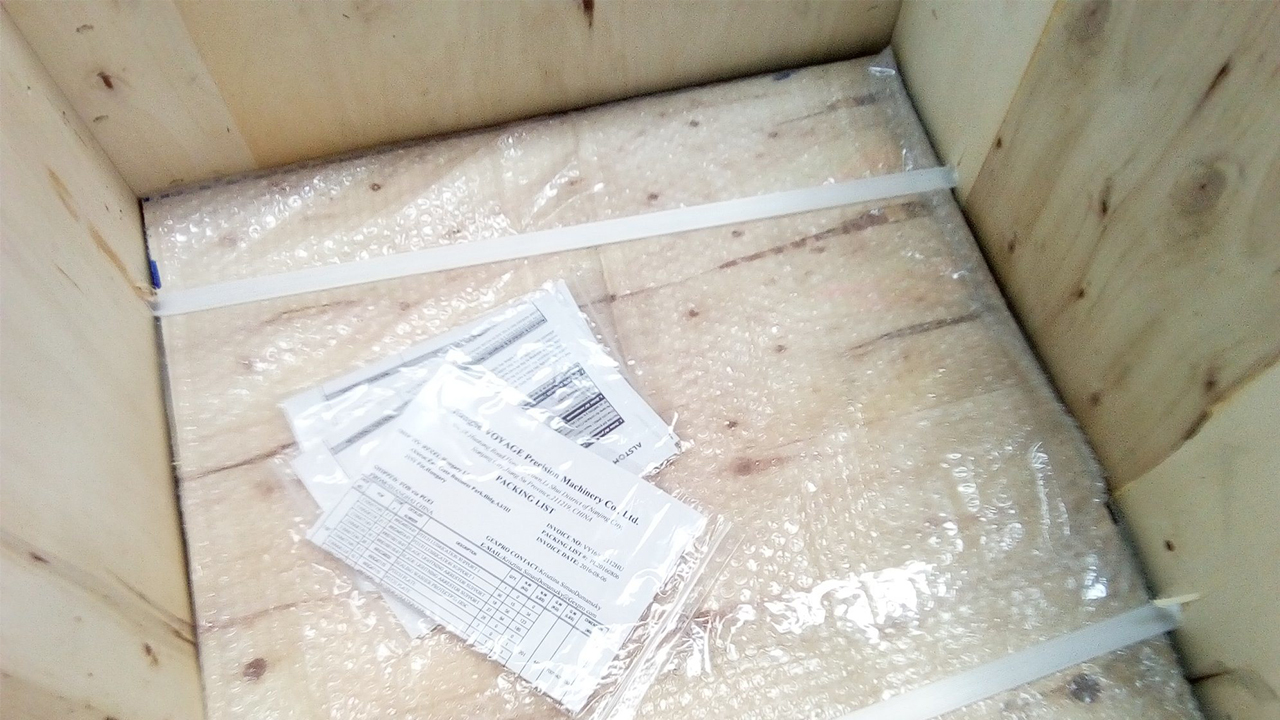

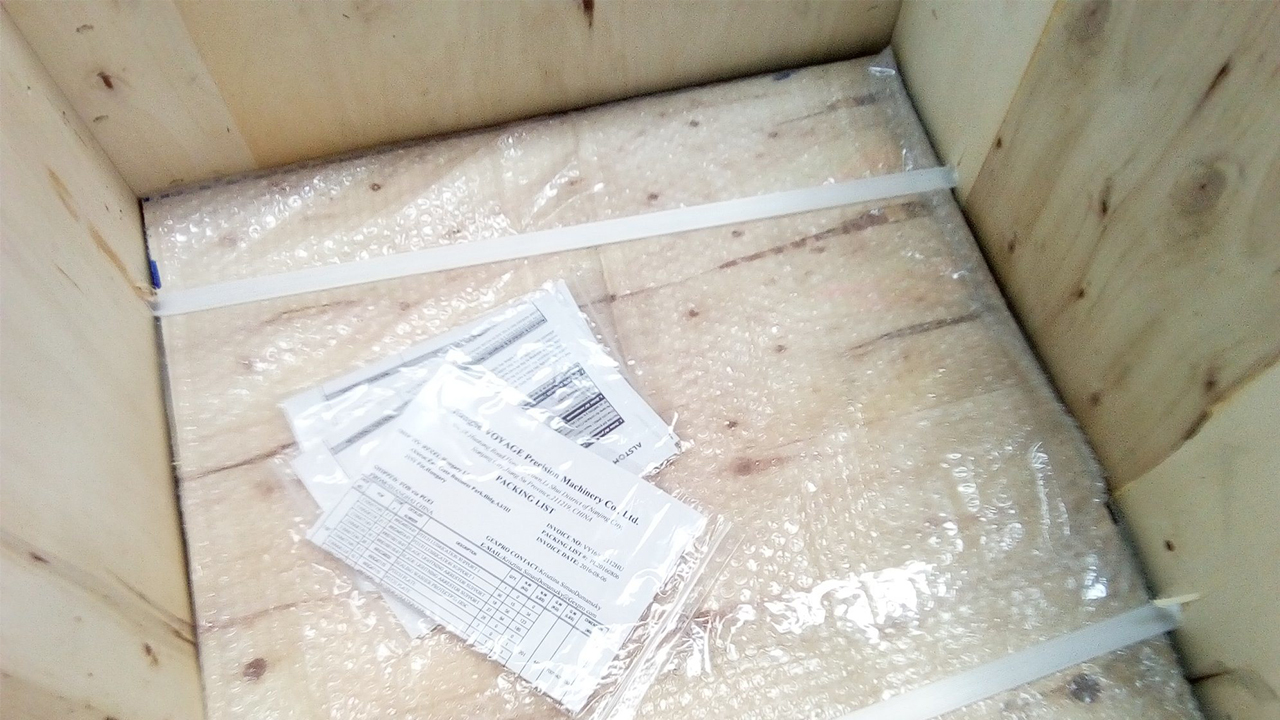

Our products are carefully packaged and placed in custom-made wooden cases, each component is gently wrapped in pearl cotton or bubble wrap to ensure gentle care during transportation. We then use strong binding straps to secure the wooden cases, ensuring that they are structurally stable and leave no room for movement. In the crevices of the wooden cases, we have carefully filled with soft chips to provide an additional layer of protection against any possible impact and friction. This thoughtful packaging process not only ensures the stability of the product during transportation, but also minimizes the risk of damage or contamination, reflecting our ultimate pursuit of product quality and customer satisfaction. We are committed to providing the safest and most reliable shipping experience for your products through every detail.

| FAQ

1. Are you a trading company or a manufacturer ?

A: We are a manufacturer with more than 15 years of experience in the metal products industry and we are committed to providing our customers with excellent products and services.

2. How much is the freight ?

A: The freight cost is determined based on your chosen mode of shipping and the quantity. Please provide us with the specific mode of transportation (either by sea or by air) and the destination port or airport to get an accurate estimate.

3. Do you accept retail order ? What is the MOQ required ?

A:Yes, we do accept retail orders. The Minimum Order Quantity (MOQ) is negotiable. Please feel free to contact us for further discussion.

4. Do you offer ODM or OEM services ?

A:Certainly, we provide both OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services. If you have a specific design in mind, please share your design blueprint with us; sending an original sample would be even more beneficial for us to understand your exact requirements.

We manage the entire process from conception to the final product within our facility, encompassing every stage such as design conceptualization, prototype review, tooling, and actual production.

|

Product Description

The bracket of the wind turbine tower barrel door is the key support structure of the tower barrel entrance, which uses a strong and durable material to ensure the stable opening and closing of the door. These brackets are well designed to withstand strong winds and other adverse weather conditions, while providing the necessary protection to prevent doors from accidentally closing or being damaged by wind. The stability of the support is essential to ensure the safe access of maintenance personnel to the tower barrel, and is usually equipped with a locking mechanism to ensure that the door is fixed when working inside the tower barrel. In addition, the design of the bracket also needs to take into account corrosion resistance and long-term maintenance convenience to meet the long-term operational needs of the wind farm.

|

Product Display

|  |

|  |

| Company Profile

Jiangsu VY Precision Machinery Co., Ltd.

Nestled in the esteemed Honglan Industrial Concentration Area of Lishui District, Nanjing—a city steeped in history and once the capital of six dynasties—Jiangsu VY Precision Machinery Co., Ltd. covers an expansive 35,000 square meters with a sophisticated construction area of 28,000 square meters. The company proudly boasts a registered capital of 20 million yuan.

Founded in 2009, Jiangsu VY Precision Machinery Co., Ltd. has flourished into a powerhouse in precision CNC machining for metal structures. Equipped with an extensive array of imported numerical control cutting, sheet metal processing, welding, and machining equipment, we offer unparalleled precision and scale. Our dedication to quality is underscored by our ISO 9001 International Quality Management System Certification, ISO 14001 International Environmental Management System Certification, and OHSAS 18001 International Occupational Health and Safety Management System Certification. Additionally, we hold prestigious qualifications such as ISO 3834 and EN1090 certification. Our core expertise lies in the design, manufacturing, and servicing of top-tier energy equipment.

|

Production Process

Cutting

Machining

Bending

Corrosion Protection

Welding

Packing

|

Certifications

ISO9001

ISO45001

ISO14001

EN1090

| Packaging & Shipping

Our products are carefully packaged and placed in custom-made wooden cases, each component is gently wrapped in pearl cotton or bubble wrap to ensure gentle care during transportation. We then use strong binding straps to secure the wooden cases, ensuring that they are structurally stable and leave no room for movement. In the crevices of the wooden cases, we have carefully filled with soft chips to provide an additional layer of protection against any possible impact and friction. This thoughtful packaging process not only ensures the stability of the product during transportation, but also minimizes the risk of damage or contamination, reflecting our ultimate pursuit of product quality and customer satisfaction. We are committed to providing the safest and most reliable shipping experience for your products through every detail.

| FAQ

1. Are you a trading company or a manufacturer ?

A: We are a manufacturer with more than 15 years of experience in the metal products industry and we are committed to providing our customers with excellent products and services.

2. How much is the freight ?

A: The freight cost is determined based on your chosen mode of shipping and the quantity. Please provide us with the specific mode of transportation (either by sea or by air) and the destination port or airport to get an accurate estimate.

3. Do you accept retail order ? What is the MOQ required ?

A:Yes, we do accept retail orders. The Minimum Order Quantity (MOQ) is negotiable. Please feel free to contact us for further discussion.

4. Do you offer ODM or OEM services ?

A:Certainly, we provide both OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services. If you have a specific design in mind, please share your design blueprint with us; sending an original sample would be even more beneficial for us to understand your exact requirements.

We manage the entire process from conception to the final product within our facility, encompassing every stage such as design conceptualization, prototype review, tooling, and actual production.